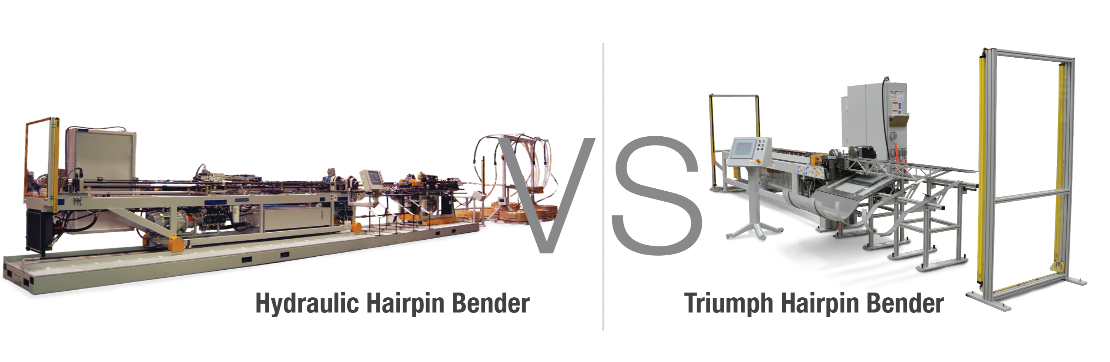

Old Hydraulic Hairpin Bender

-

Least upfront costs

-

Lots of down time

-

Poor hairpin quality

-

High scrap rate

Repaired/Refurbished Hydraulic Hairpin Bender

-

Can cost as much as a new Triumph Hairpin Bender

-

Long setup times for length change

- Nonparallel hairpins cause difficulty during lacing process

- Inconsistent leg lengths

- Overall lower productivity and hairpin quality

New Triumph Hairpin Bender

-

70% more productivity

-

1 hour tooling changeover

-

30 second maximum length changeover

-

Lower scrap rate

-

Lower maintenance costs

-

Lower cost per hairpin

-

Process control delivers consistent and accurate leg lengths

-

Touch screen interface improves set-up time

-

Considerably less hydraulic components

Media & Materials

Learn more about the Triumph Hairpin Bender by clicking the link below.