OAK 4.0

OAK 4.0

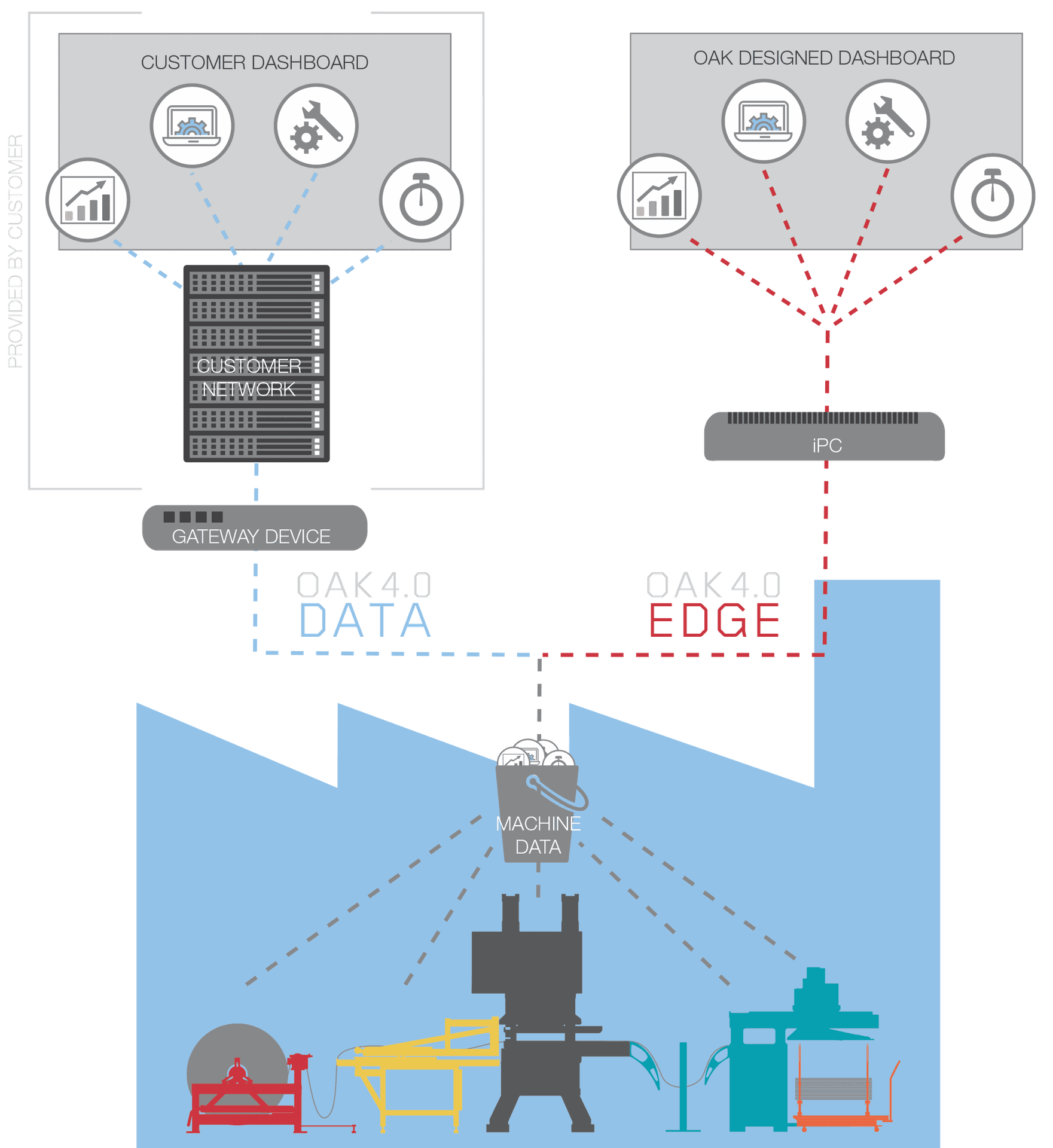

OAK 4.0 allows end users to collect data that will empower better operational decisions. This feature enables OAK machines to provide operational data to the end user's production system for refinement and reporting purposes. These reports can be utilized to analyze production metrics, optimize asset management, and proactively schedule machine maintenance.

OAK 4.0 provides you smart, connected machines that will help you optimize your plant's operations. Our goal is to enable you to gather the data from OAK machines that you need to take your business to the next level of intelligence, realize actionable insights, and improve your asset management and maintenance.

Burr OAK Tool currently provides two different options for adding OAK 4.0 to your OAK machinery.

Data

- Provides customers access to read and write data inside the machine

- Customer is responsible for collecting and analyzing data

Edge

- Industrial PC added to the machine

- Perform basic data processing and analysis

- Display processed data on dashboards

- View dashboards locally at machine (customer provided monitor)

- View Dashboards via web browser on network computer

Advantages

Predictive / Preventative Maintenance

-

Tool sharpening / replacement (ie., pierce punch, cutter blade, or expander bullets)

-

Machine cleaning schedule determined by cycles or hours in operation

-

Lubrication / oil refill schedule

-

Servo performance logs

Machine Monitoring

-

Log diagnostic messages and error messages for trouble shooting

-

Servo torque graphs to review anomalies

-

Real world data that helps OAK refine machine design and process improvement

-

Electronic components reduce hydraulic requirements

Production Metrics

-

Machine utilization rates

-

Production rates (TAKT time) to refine scheduling machine capacity

-

Real time schedule attainment reporting

Optimize Operations

-

Digitalization

-

Virtualization

-

New information flows

-

Real-time product tracking

-

Predictive Maintenance

-

Anomaly detection

-

Production control

-

Diagnostic assistance

-

Data management services

-

Data Visualization

-

Performance insight

-

Remote monitoring services

-

Asset management

-

Cognitive solution

-

Business intelligence

-

Visibility to actionable intelligence

Materials & Media

Capital Sales

To request a quote or learn more about OAK 4.0 visit our capital sales page.