Lubrication Solutions

Accurate. Consistent. Efficient.

Heat exchange manufacturers know that lubrication is a critical factor that

can help ensure productivity in fin making operations. As a world leader in

the design and manufacture of fluid dispensing solutions, Unist surpasses

the demands of the HVAC industry by providing lubrication solutions that

improve efficiency and productivity.

Precision Lubrication Benefits

Increase punch life

Reduce downtime

Consistent fin weights

Reduce fluid consumption

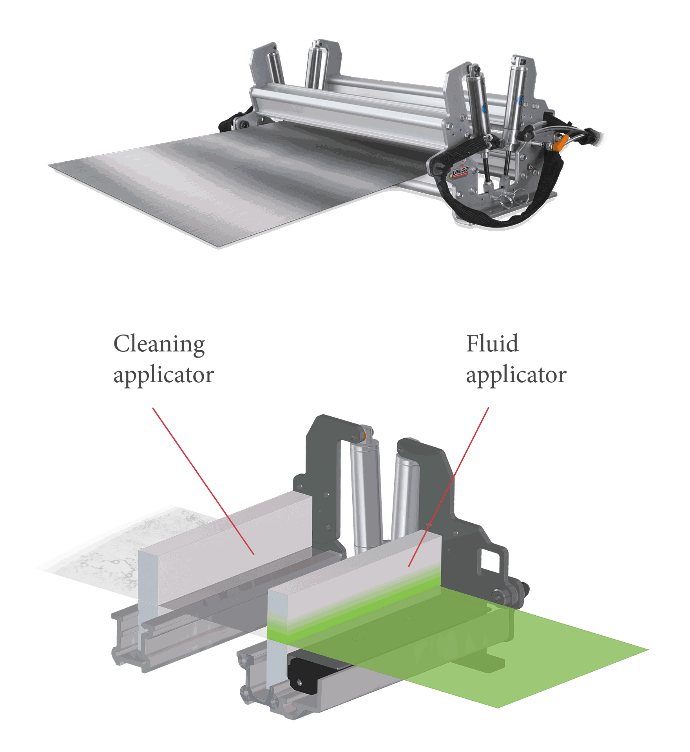

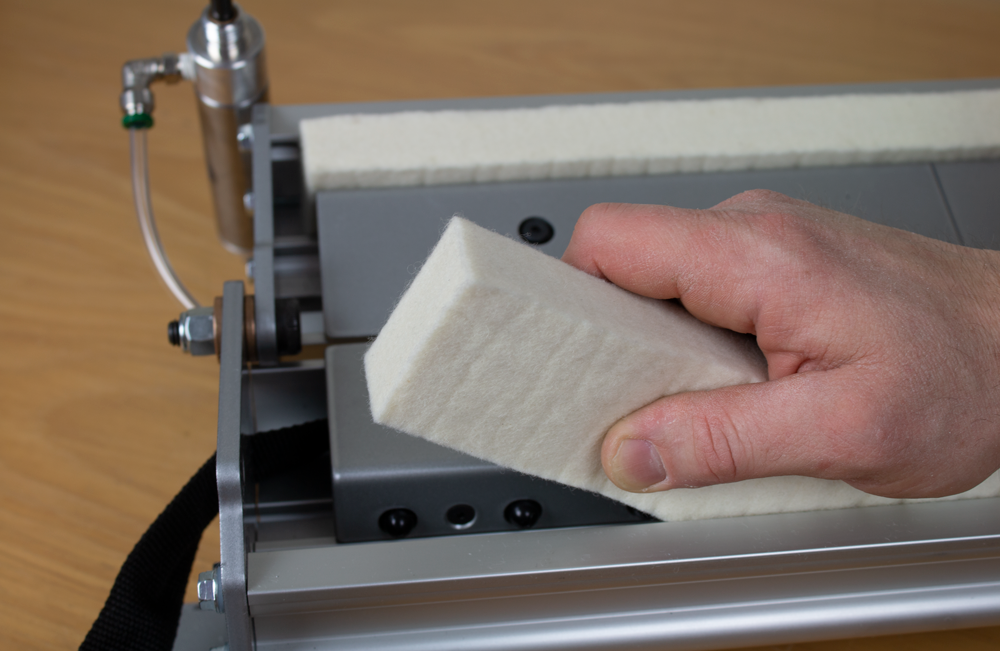

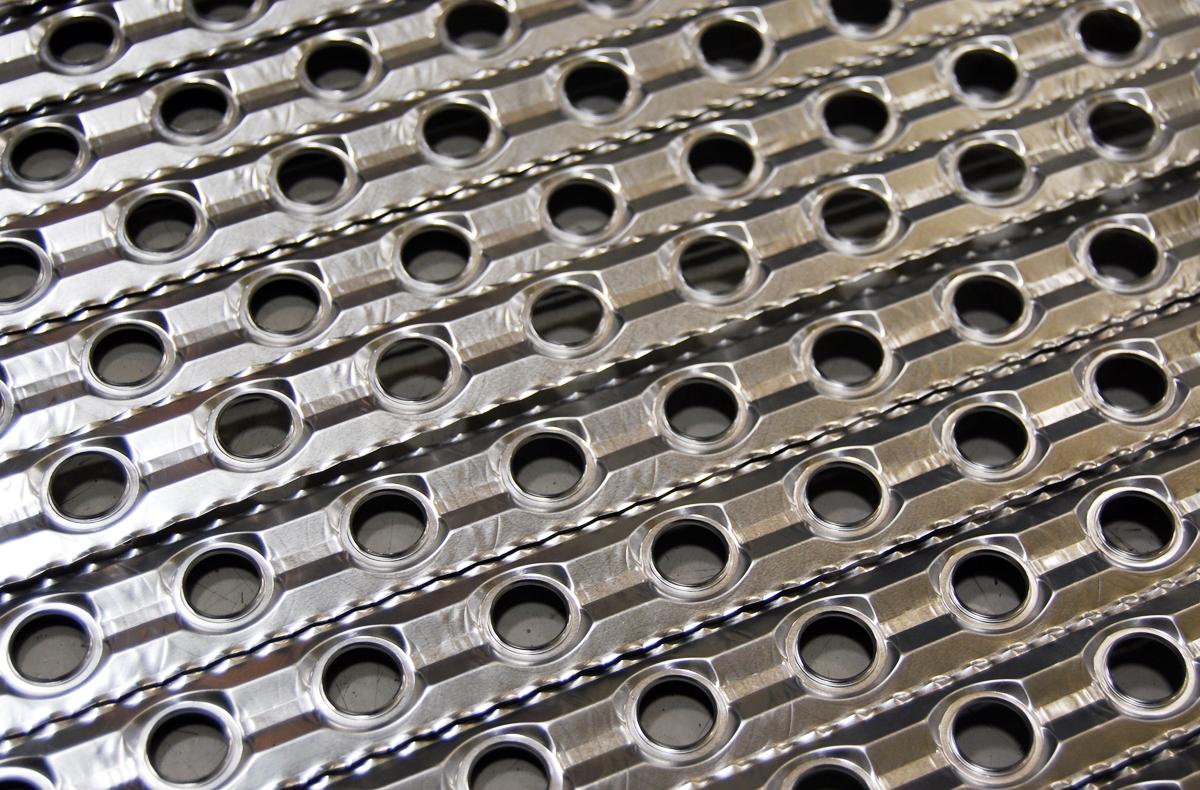

E-Lube

The OAK E-Lube is the ideal solution for precisely and accurately applying fin stamping fluids. The robust applicator utilizes specially engineered felt applicators to wipe a thin film of lubricant onto the stock material - top and bottom. With fluid supplied by the SmartFlow® fluid controller, the E-Lube allows manufacturers to program the exact amount of oil needed to run the fin press at peak performance while providing maximum protection to the tooling. With proven success on hundreds of fin presses around the world, the OAK E-Lube Fluid Applicator is the ultimate option for lubrication fin stock.

-

Precise application of oil for all jobs or collar heights

-

Even and consistent stock coating stock as light as 50mg/ft2

-

Track oil consumption

-

Wiper bar cleans stock before the lubricant applicators

-

Cleaner application than dip tanks, spray nozzles, or electrostatic lubrication

-

Built-in alert monitoring

-

Compatible with a broad variety of fluids

-

Easy to change felt applicators

-

Coat stock from 9" to 45" wide

Easy felt applicator replacement

Cleans & lubricates

Individually controlled applicator pressure

No excess oil

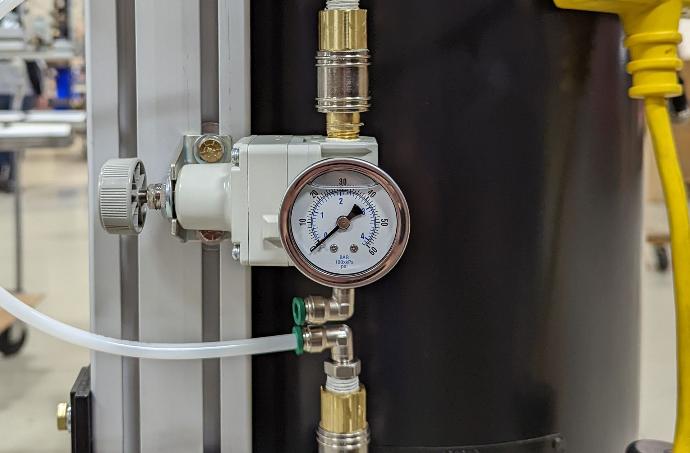

SmartFlow®

SmartFlow® lets you take full control of stock lubrication on your

fin press. With SmartFlow®, creating lubrication jobs is quick and

simple. SmartFlow® monitors the lubrication process, tracks fluid

consumption, and alerts operators to any lubrication issues.

Designed around an easy-to-use operator interface, the SmartFlow®

provides a guided setup designed to help HVAC manufacturers

deliver the exact amount of fluid that their job requires. Fluid film

thicknesses can be independently adjusted on top and bottom of the

material, as well as across the width in 9” zones.

Pierce & Enhance Oiling System

The pierce and enhance stations are the critical areas of a fin die. Protect

these vital areas by adding Unist’s state of the art Pierce and Enchance (P&E) Oiling System and gain the accuracy and repeatability that other systems and improvised methods lack. The P&E Oil System uses reliable positive displacement pumps to deliver lubricant consistently regardless of changes in fluid viscosity. Users can precisely dial in the amount of lubricant delivered to the pierce and enhance die stations and monitor the flow of oil to ensure consistent lubricant delivery. When installed with a SmartFlow®, oil can be supplied directly from the SmartFlow’s®existing oil tank. The P&E Oil System is designed to retrofit onto Burr OAK Tool fin processing lines, using existing control signals for operation.

-

Industry proven positive displacement pumps

-

Precision oil delivery

-

Easy to use touchscreen interface

-

Password protection

-

Retrofittable

-

Improved diagnostics

-

Reduced footprint vs. conventional systems

-

Simplified installation

Materials & Media

Capital Sales

To request a quote or learn more about BOTI FP-1400 Fin Press visit our capital sales page.