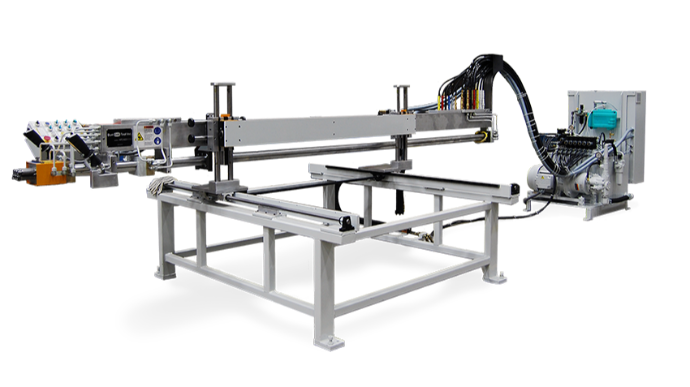

Horizontal Progressive Expander

Flexible Expansion at a Modest Price.

The OAK Horizontal Progressive Expander uses small bore hydraulic cylinders to expand heat exchange coils with little damage. Tension expanding either straight lengths or both legs of hairpin tubes provides uniform results with no fin damage.

These machines are versatile and can be set up for different coil configurations in just a few minutes. They are also capable of providing high expansion forces for expanding stainless steel and other exotic tubing materials.

Machine Facts

PRODUCTION

70' (21 m) / min

(single hairpin running light wall copper)

Additional cylinders will reduce the speed.

FOOTPRINT

Support Table: 78" (1.98 m) wide x 66" (1.7 m ) long

Max coil length: 20' (6 m) long

WEIGHT

3,300 lbs (1,500 kg)

AIR SUPPLY

8 ft3/min at 80 psi (0.23 m3/min at 5.6 bar)

POWER SUPPLY

Requirements for 3-4 tube HPE: 13 kW @ .80/.82 PF, 24 VDC Controls

Foundation information supplied upon request.

TUBE SPACING

.63" (16 mm) minimum distance between tubes

CYLINDERS

Up to 7 cylinders

TUBING DIAMETER

.312” (8mm) to 1" (25.4 mm) OD

TUBING MATERIAL

- Copper (Cu)

- Aluminum (Al)

- Stainless Steel (SS)

- Cupronickel (CuNi)

Advantages

Economic

-

Less expensive than vertical expanders.

-

Minimal setup time.

-

Fast expansion speeds of 70'/min (21 m/min).

Technical

-

No trimming or end-forming of tube after expansion due to hydraulic collet actuation.

-

Use for long tubes up to 2' (6 m ) vs. 12' (3.65 m) max for vertical expanders.

User

-

Ideal for diagonal hairpins; no need to rotate machine to align with tubes.

-

Simpler to operate than competitive horizontal expanders due to support table, automatic lubrication and less setup time.

Materials & Media

Capital Sales

To request a quote or learn more about BOTI's Horizontal Progressive Expander visit our capital sales page.