OAK High Speed Fin Line

High Speed Fin Line

The Benchmark for High Speed Fin Production

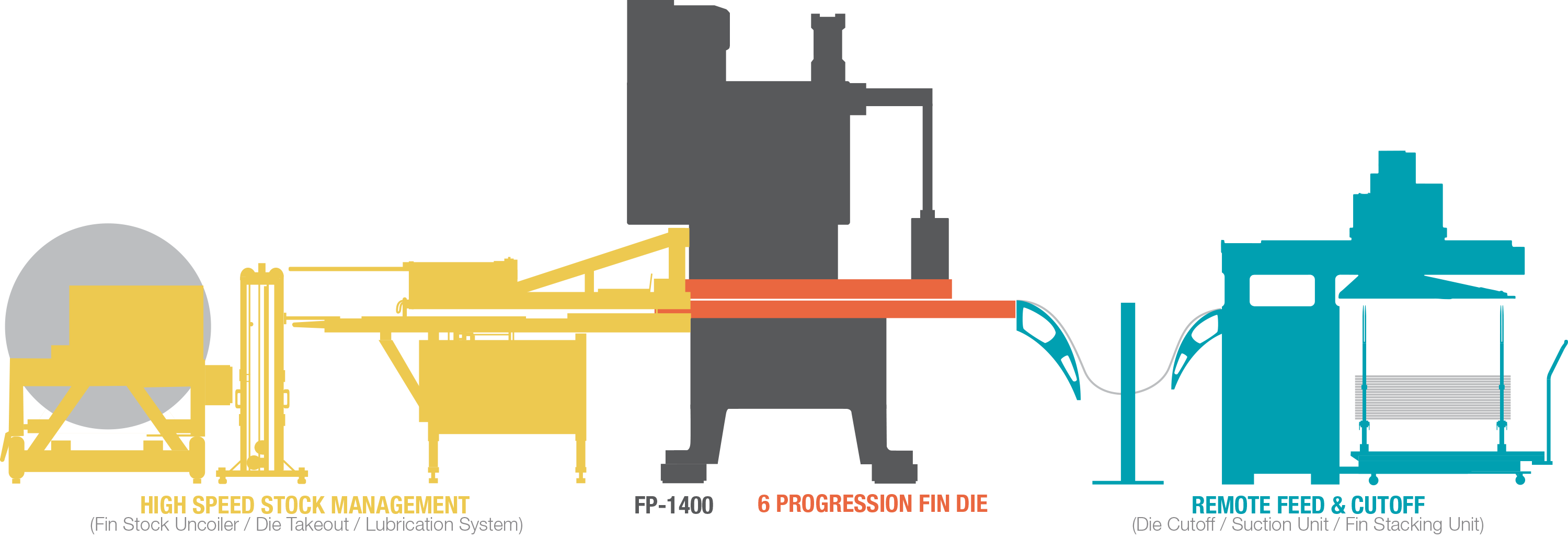

The OAK High Speed Fin Line combines our world class stamping press with a remote feed and cutoff stacking unit and a state of the art servo controlled material handling system. This combination of equipment can achieve production speeds of up to 400 SPM*, and when combined with an OAK 6 Progression Dies, can double your fin production when compared to a standard fin line.

Machine Facts

PRODUCTION

Capable of speeds up to 400 SPM

*Application Dependent

FOOTPRINT

17' (5.18 m) x 45' (13.72 m)

WEIGHT

Varies depending on what press is purchased

AIR SUPPLY

120 - 200 SCFM at 85 psi(3.4 - 5.6 m 3 /min at 6 bar)

POWER SUPPLY

Available by request

Components Of The High Speed Fin Line

Stock Management

Burr OAK Tool's new stock management system and uncoiler is synchronized with the fin press's servo feed system. This synchronization provides the fin die with the precise amount of material required during each stroke of the press to promote up to 400 SPM continuous fin production.

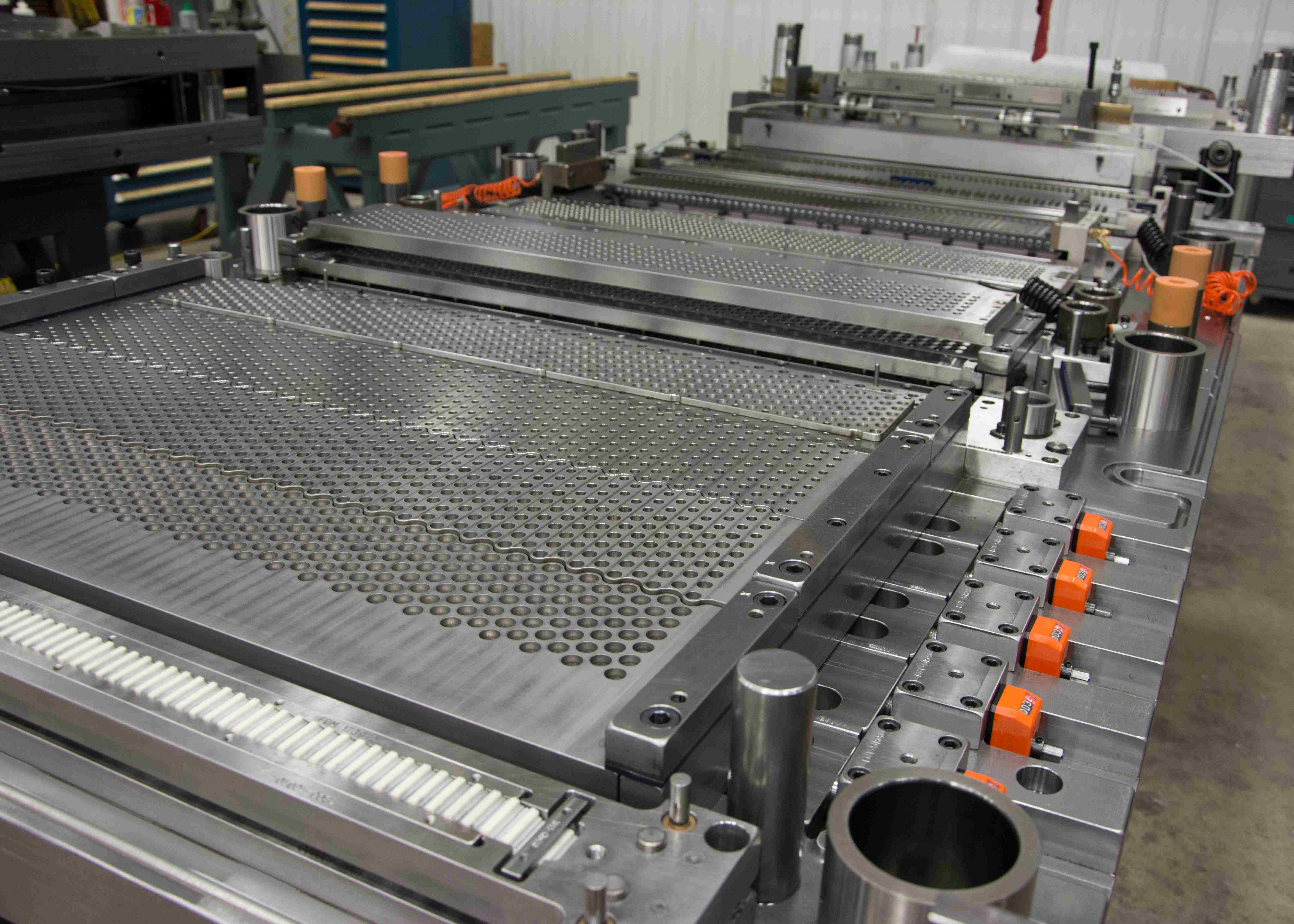

OAK 6 Progression Die

A 6 progression fin die with high speed fin line, RFCM, and new material handling system will allow for up to twice the fin production of a standard fin line with 4 progression fin die.

RFCM

The Remote Feed and Cutoff (RFCM) feature for OAK Fin Lines delivers improved speed, production capacity, and quality for your fin production operation. The remote Feed and Cutoff allows the fin press and stacker to run independently from one another, enabling smooth, continuous operation of the entire line. The RFCM also eliminates the need for a die progression change since fins are able to be stamped continuously and then remotely cut to length, producing a high-quality, sliver-free fin.

Advantages

Economic

-

Increased production

-

Elimination of progression changes

-

Elimination of slit slivers

- Improved stacking

- Improved fin accuracy

Technical

-

Driven spindle uncoiler with electronic braking

-

Electronic servo controlled material handling system

-

Continuous motion fin stacking

-

Laser measured slack loop control

-

Increased capacity press feed

User

-

Eliminates progression changes in traditional fin dies, therefore eliminating restrike and sliver issues

Materials & Media

Capital Sales

To request a quote or learn more about High Speed Fin Line visit our capital sales page.