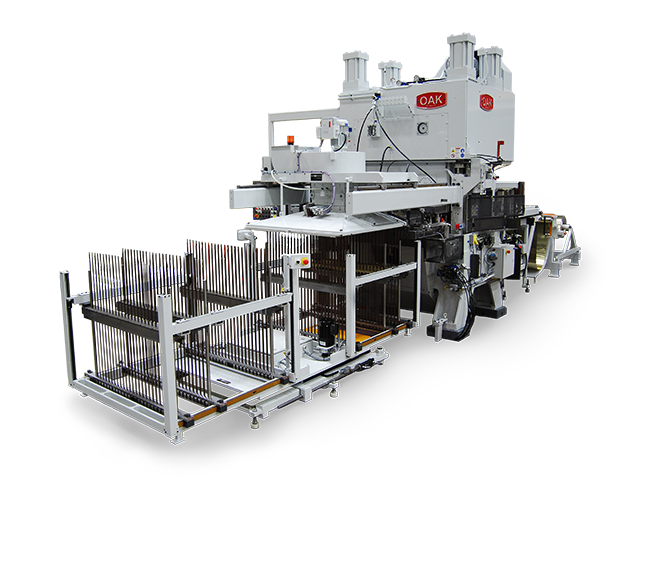

FP-1400 Fin Press

Big, Brawny, Balanced.

This high performance press and line for the heat transfer industry has a 160-ton (1,400kN) rating for increased fin stamping capacity. Extensive solid modeling performed in the design stage and added weight optimize press rigidity. The new electronic servo-feed allows easier access to the left side of the press and die, and centers and balances the forces on the feed shaft. It also allows the press operator to program the fin length from the touch screen on the control panel. The dynamically balanced platform minimizes vibrations, ensuring accuracy even at higher press speeds. In almost any fin making application the FP-1400's size, strength and stability will increase capacity and improve performance.

Machine Facts

PRODUCTION

160 to 400 SPM*

FOOTPRINT

3.7 m x 10.1 m (12’ x 33’)

WEIGHT

~ 19,000 kg (41,800 lbs)

AIR SUPPLY

120 - 200 SCFM at 85 psi

(3.4 - 5.6 m3/min at 6 bar)

POWER SUPPLY

64 kW @ .80/.82 PF, 24 VDC Controls

Foundation information supplied upon request

TONNAGE

160 US Tons / 1,400 kN

FIN LENGTH

Up to 108" (2,742 mm)

FIN WIDTH

Up to 37" (940 mm)

SHUT HEIGHT

9" (230 mm) - 13" (330 mm)

STANDARD STROKE

1" (25 mm) - 3" (76 mm)

Advantages

Economic

-

Dynamically balanced for less vibration, therefore reducing maintenance.

-

Electronic feed reduces setup downtime thus increasing overall production.

-

160 ton press provides higher production in a given floor space.

Technical

-

Electronic feed saves wear and tear on feed components.

-

4-point load on side ensures accurate load distribution to product consistent fin dimensions across the die.

-

Hydraulic system for adjusting shut height allows flexibility in die designs.

-

Hydraulic withdrawal system allows routine maintenance without removing the die from the press.

-

Programmable Logic Controller (PLC) stops fin production automatically when a predetermined number of fins have been stacked.

User

-

Can be modified to allow a maximum stroke length of 3" (76mm) if necessary.

-

Electronic feed requires less training for operator company.

-

Perform maintenance without using a forklift or crane to remove the die from the press.

-

Includes new features for stock feeding, lubrication and fin collection to increase ease of operation and productivity.

-

Thicker and high tensile materials are easier to manipulate with the 160 ton press and will operate high production fin dies.

-

Program the fin length from the touchscreen control panel.

Materials & Media

Capital Sales

To request a quote or learn more about BOTI FP-1400 Fin Press visit our capital sales page.